🌍 1. Introduction

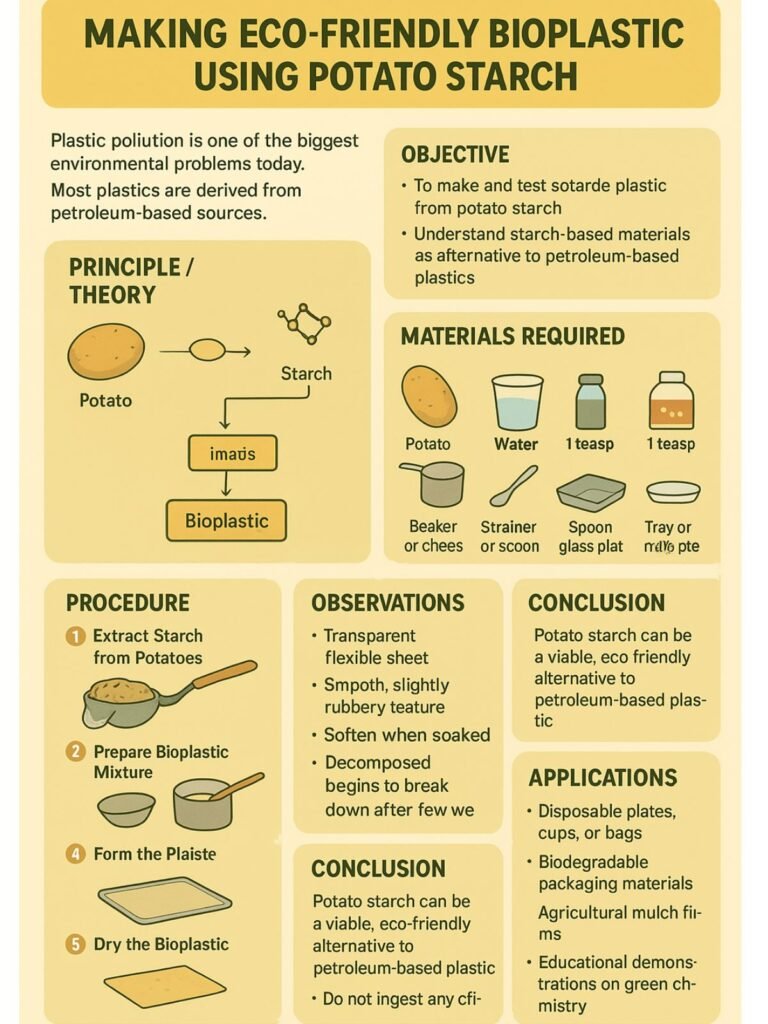

Plastic pollution is one of the biggest environmental problems today. Most plastics are made from petroleum and take hundreds of years to decompose.

To reduce this pollution, scientists are developing bioplastics — plastics made from natural materials like starch, corn, or potatoes that can biodegrade easily.

In this project, we will make a simple bioplastic using potato starch, showing how natural materials can replace harmful synthetic plastics.

🎯 2. Objective

- To make a simple biodegradable plastic from potato starch.

- To understand how starch-based materials can be used as an eco-friendly alternative to petroleum-based plastics.

- To promote awareness about sustainable and green chemistry.

🧠 3. Principle / Theory

Potatoes contain starch — a carbohydrate made of glucose chains.

When starch is heated with water, glycerin, and vinegar, it forms a gel-like paste that solidifies into a plastic-like material when cooled.

- Starch → provides polymer chains

- Glycerin → acts as a plasticizer (makes it flexible)

- Vinegar (acetic acid) → breaks some bonds in starch, helping it dissolve evenly

- Heat → allows all ingredients to react and form bioplastic film

🧰 4. Materials Required

| Item | Quantity | Purpose |

|---|---|---|

| Potato | 2 medium-sized | Source of starch |

| Water | 100 ml | Solvent |

| Vinegar (acetic acid) | 1 teaspoon | Reactant |

| Glycerin | 1 teaspoon | Plasticizer |

| Stove or hot plate | — | Heating |

| Beaker or saucepan | 1 | Mixing |

| Strainer / cheesecloth | 1 | Extracting starch |

| Spoon, measuring cup | — | Mixing |

| Tray / glass plate | 1 | For drying bioplastic sheet |

⚗️ 5. Procedure

- Extract Starch from Potatoes:

- Peel and grate the potatoes into a bowl of water.

- Stir well and strain the mixture using a cloth.

- Allow the liquid to settle for 1–2 hours.

- You’ll find white starch at the bottom — pour off the water and collect the starch.

- Prepare Bioplastic Mixture:

- In a pan, add:

- 1 tablespoon of potato starch

- 100 ml water

- 1 teaspoon glycerin

- 1 teaspoon vinegar

- Stir the mixture thoroughly.

- Heat the Mixture:

- Heat slowly while stirring until it becomes clear and thick (gel-like).

- Avoid burning.

- Form the Plastic Sheet:

- Pour the warm mixture onto a clean glass plate or tray.

- Spread it evenly using a spatula.

- Dry the Bioplastic:

- Let it dry at room temperature for 24–48 hours.

- Once dry, peel off the bioplastic film.

🔬 6. Observations

| Property | Observation |

|---|---|

| Appearance | Transparent, flexible sheet |

| Texture | Smooth, slightly rubbery |

| Reaction to water | Softens when soaked |

| Decomposition | Begins to break down after a few weeks |

📊 7. Results

The potato starch successfully formed a thin, flexible, transparent bioplastic sheet.

This plastic biodegraded easily and did not produce toxic fumes when burned — unlike synthetic plastic.

🌱 8. Conclusion

This experiment proves that potato starch can be used to make biodegradable plastic.

Bioplastics are an eco-friendly alternative that can help reduce environmental pollution caused by synthetic plastics.

With further research, this method can be improved for industrial use.

💡 9. Applications

- Making disposable plates, cups, or bags

- Biodegradable packaging materials

- Agricultural mulch films

- Educational demonstrations on green chemistry

⚠️ 10. Precautions

- Heat the mixture slowly to avoid burning.

- Handle hot mixture carefully.

- Dry the plastic sheet completely before testing.

- Do not ingest any chemicals.

🧾 11. Future Scope

With improved techniques and additives, starch-based plastics can become stronger and more water-resistant.

Using waste potatoes or corn waste could make bioplastics cheaper and more sustainable in the future.

📸 12. Project Display Ideas

- Include a bioplastic sample sheet on your chart.

- Show pictures of each step (grating, filtering, drying).

- Add a comparison chart: Bioplastic vs Synthetic Plastic.

- Use bright posters and eco-friendly decorations for presentation.

No responses yet